Make Your Collection One of a Kind

Customization

At YcNeo, we don’t just create high-quality handcrafted frames—we offer customization services to make your comic display truly unique. Choose from custom sizes, colors, finishes, engravings, and special display features for signed or graded comics. Every custom frame is crafted with the same precision and craftsmanship as our standard products, ensuring top-tier quality and a stunning showcase for your collection.

📩 Looking for a custom frame? Let’s create something unique together!

📧 Email us at: ycneoteam@gmail.com

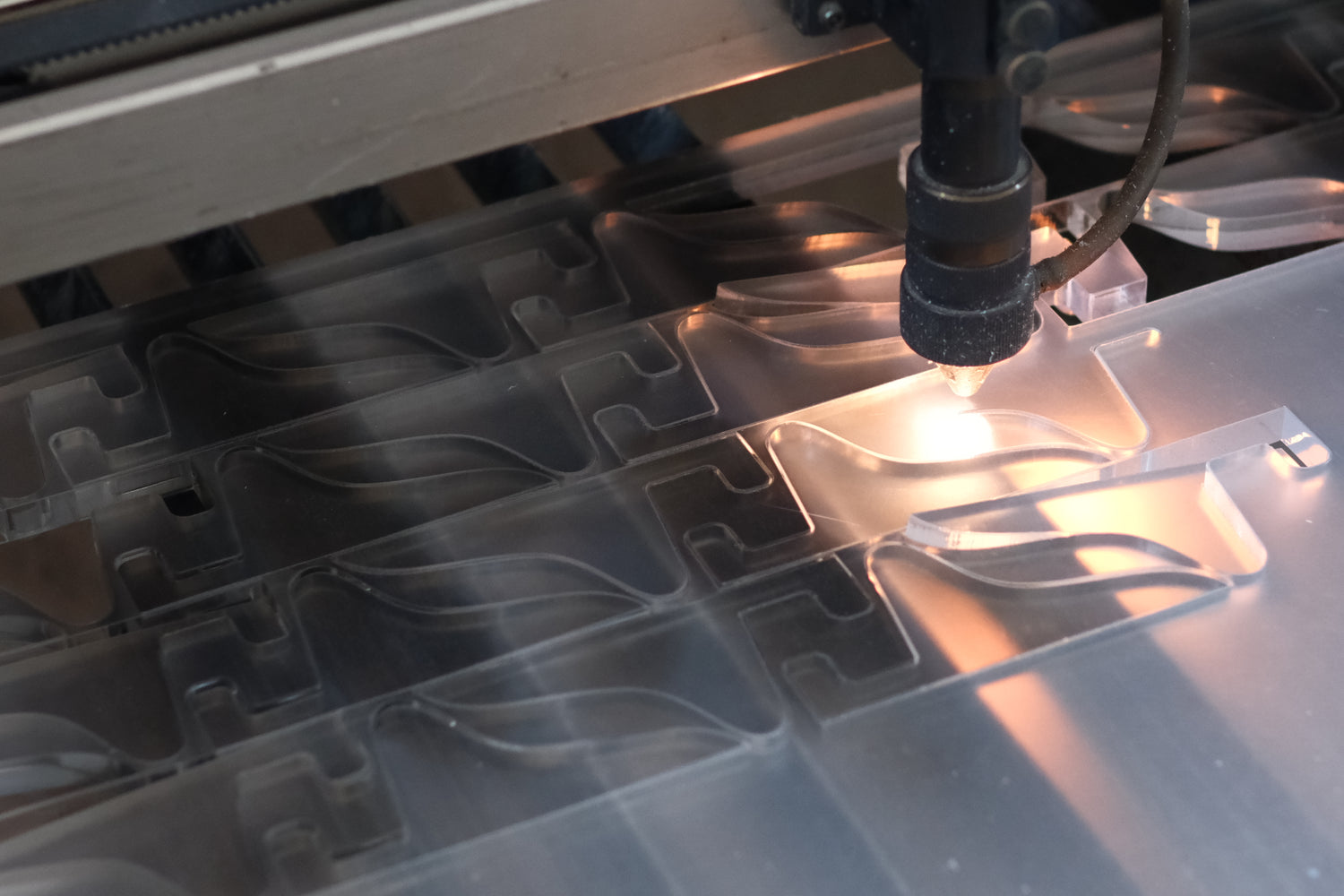

1. Machine Cutting

At YcNeo, we begin with custom high-quality acrylic sheets that offer 90%-99% UV protection and light transmittance, precisely cutting them to the required dimensions with specialized equipment to prepare for the subsequent processes.

2. CNC Laser Cutting

We use CNC laser cutting with pre-set program data to precisely cut each product. This ensures the acrylic edges remain clear and smooth, maintaining transparency and flatness. CNC laser cutting guarantees top quality in both appearance and functionality, providing a solid base for the next assembly steps.

3. Diamond Abrasive Polishing

In this step, YcNeo uses diamond abrasive polishing to smooth and flatten the edges of our products. This ensures a refined, flawless finish, enhancing both appearance and quality. It also improves durability by minimizing surface imperfections, reducing the risk of cracks or chips, and increasing the transparency of the edges.

4. High-Precision Drilling,Magnet Embedding

A craftsman with 30 years of experience carefully drills holes into the acrylic sheets and embeds magnets with precise force. This ensures accurate placement and secure attachment, enhancing both functionality and aesthetics.

5. Flame Polishing

We uses a flame generated by oxyhydrogen gas, produced through water electrolysis, reaching temperatures of 2500-3000 degrees Celsius. This flame is applied to the acrylic edges, creating a crystal-clear, polished finish. The environmentally friendly process produces zero pollution, effectively removing surface scratches and imperfections, and enhancing the overall appearance and quality of the product.

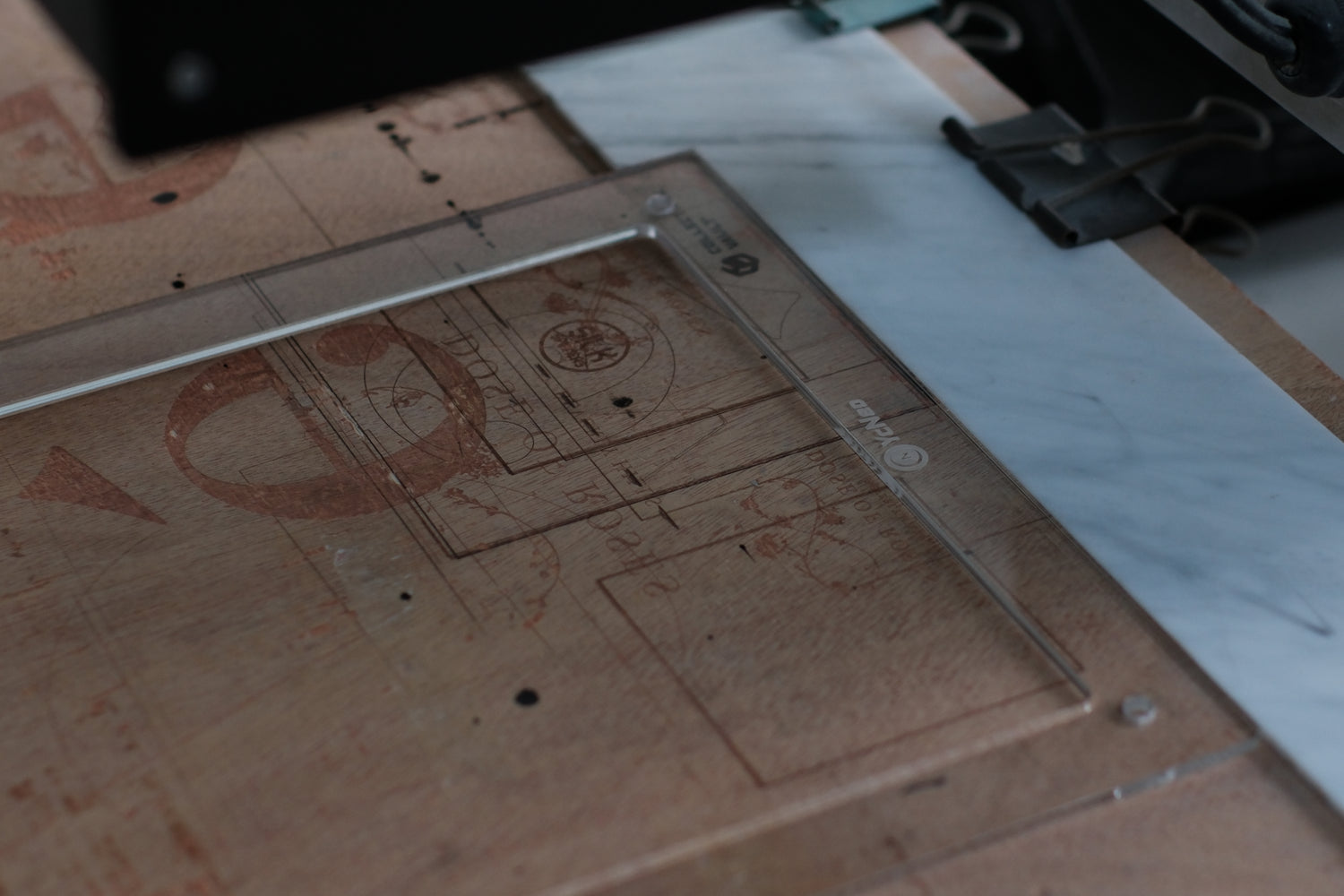

6. Laser Logo Engraving

At YcNeo, we’ve tested various materials and thicknesses to perfect our laser logo engraving. While we no longer engrave logos on all products, we offer customization options to meet clients’ specific needs.

7. Cleaning and Quality Assurance

At YcNeo, each product undergoes thorough cleaning and inspection. Our team uses industrial alcohol and soft cloths to remove dirt. Any imperfections or scratches are reprocessed with a roller machine for fine polishing, ensuring top-quality standards.

8. Manual Assembly and Packaging

Due to acrylic’s surface sensitivity, each product is carefully wrapped in protective film by hand to prevent scratches during transit. A final quality check is conducted before packaging to ensure every piece meets YcNeo’s high standards.